Reducing Heat Stress While Maintaining Thermal Protection

Article

For effective protection against fires, industrial workers must cover their bodies as completely as possible with flame-resistant (FR) clothing. This requires long pants and long sleeves, making for hot work in warm and humid climates. Understandably, workers may be concerned about potential heat stress when selecting and wearing protective apparel.

Factors that contribute to heat stress

Three factors contribute to heat stress: external conditions, including temperature, humidity and wind; type and weight of garments; and type and level of activity.

All physical activity causes our bodies to generate heat. For the body to maintain its proper temperature, this heat must be lost or dissipated through the skin and clothing. If the body cannot rid itself of excess heat, heat stress can occur.

Our bodies lose heat in two main ways:

• Dry heat transfer

When the surrounding temperature is lower than that of our skin. Because our internal body temperature is over 90°F, dry heat transfer takes place most of the time.

• Evaporative heat transfer

Sweating and sweat evaporation. Sweating leaves a layer of moisture on the skin’s surface. When this water evaporates, it cools the body. The balance between the heat our bodies create by activity and the heat they lose through dry and evaporative heat transfer determines how hot or cool we feel.

Weight matters more than fabric type

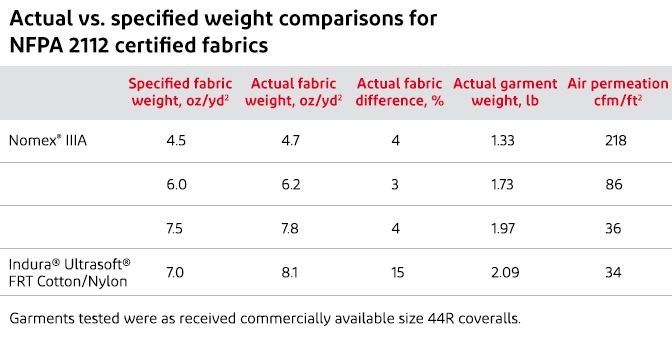

Fabric weight is more influential than fabric type on whether garment wearers suffer from heat stress. Manufacturers of FR clothing typically list the weight of the fabric in ounces per square yard (oz/yd2).

Even the lightest-weight commercially available flame-retardant treated (FRT) cotton coveralls are made from fabrics with a specified weight of 7 oz/yd2, while some commonly used FRT cotton fabrics for coveralls have a specified weight of 9 oz/yd2.

By contrast, garments made from DuPont™ Nomex® fiber and DuPont™ Protera® fabric are very lightweight. Ounce for ounce, they provide the lowest possible weight at the highest level of protection. (FRT cotton garments typically weigh a full pound or more than garments made with Nomex®.) At a weight of 4.5 oz/yd2, a garment made of Nomex® IIIA may weigh as little as 1.33 pounds.

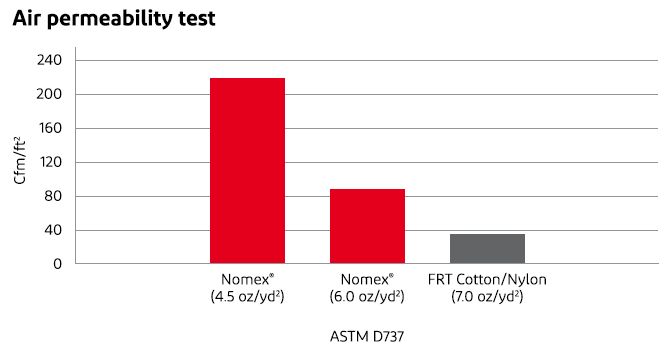

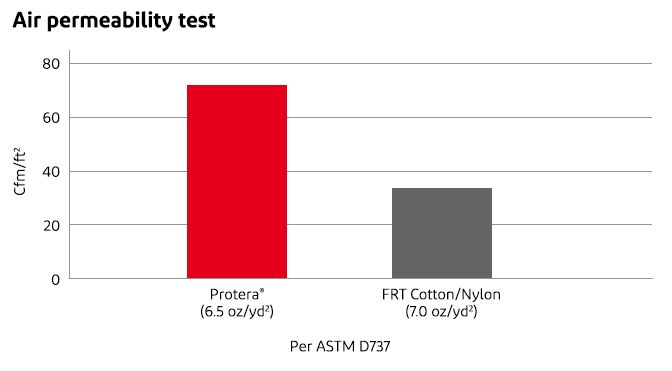

Air permeability is key

Air permeability is a fabric’s ability to let air pass through. Because most FRT offerings are treated or covered with a flame-retardant material, they are not only heavier but also have low air permeability. In contrast, garments made with Nomex® and Protera® offer up to twice the air permeability of FRT fabric.

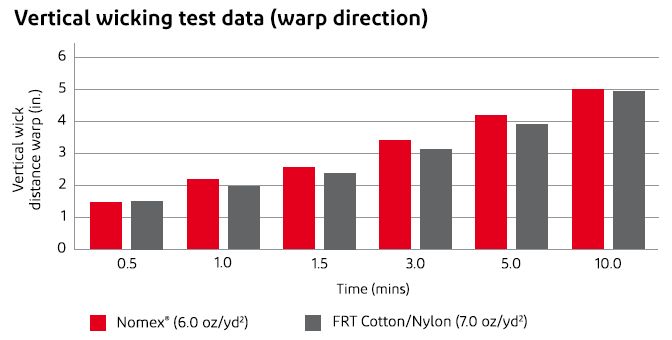

Moisture management and thermal comfort

The final factor to consider is moisture management. Once the body passes from dry heat transfer to evaporative heat transfer, a garment’s ability to wick away moisture from the body and help it evaporate is a key factor in the wearer’s perceived comfort. Garments made with Nomex® and Protera® are able to effectively wick away moisture.

Conclusion

Because multiple factors contribute to heat stress, including heat, humidity and activity level, no garment can provide 100% comfort. However, selecting appropriate FR clothing can help manage your wearer’s comfort and ensure that they avoid the factors leading to heat stress.

The flame resistance of fabric made with Nomex® fiber and Protera® fabric is not only inherent, it helps lower heat stress by providing a more comfortable garment through lighter weight, increased air permeability and improved moisture management.