Improving productivity with effective water management

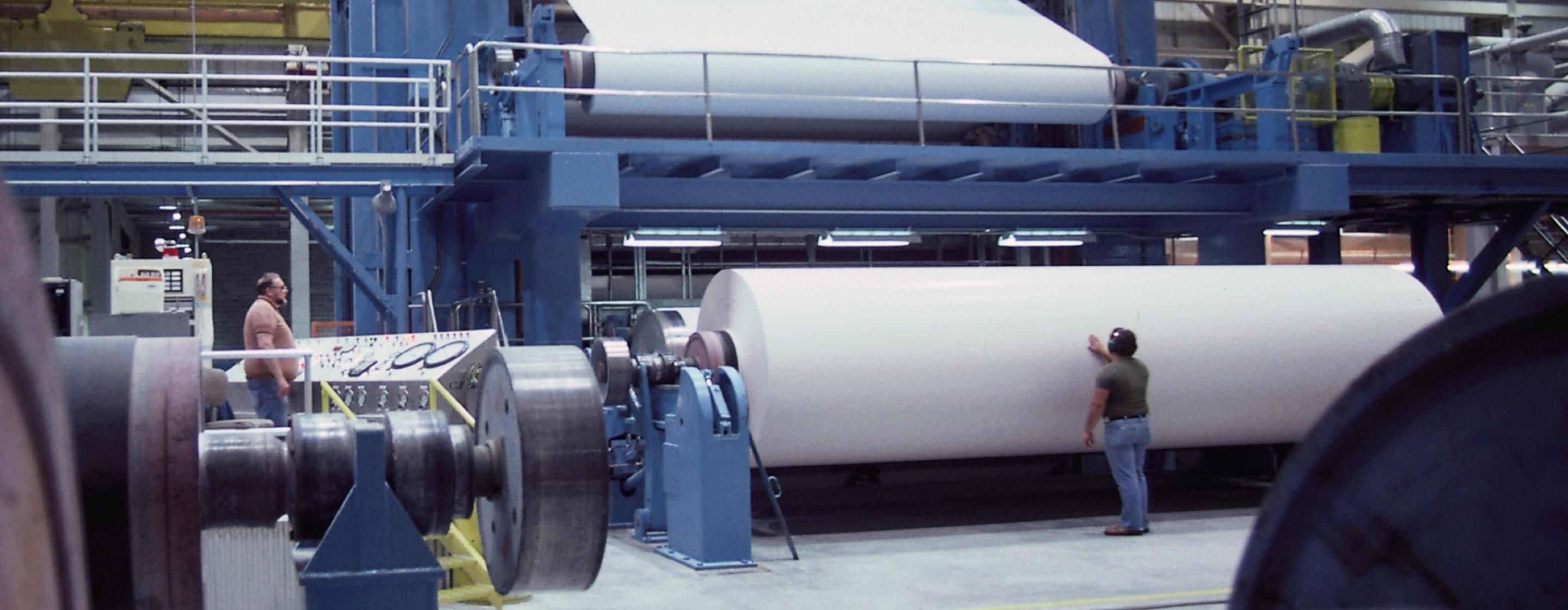

Pulp and paper mills are among the largest industrial water consumers. They need water to ensure reliable, continuous operations. But at the same time, they’re being pressed to reduce their water footprints.

Innovative technologies and industry knowledge from DuPont Water Solutions can help solve water treatment challenges — from high-purity boiler makeup water treatment to fiber removal from the waste streams — thorough the entire pulp and paper production process.

Pulp and paper subindustries and applications

Preventing water issues that slow production

Like in many processing plants, pulp and paper mills need to deal with challenging cooling tower water. If not properly filtered, cooling tower water can result in scaling, corrosion, and contamination that can adversely affect production.

Our industry-leading knowledge and local expertise in cooling water treatment can help you define a strategic solution that saves money, prevents problems, and helps better manage overall water resources.

Our solutions address:

- Cooling tower blowdown recycle.

- Suspended solids removal.

- Softening.

- Minimal liquid discharge (MLD).

Lowering costs for production

Water-treatment needs for boiler feedwater in pulp and paper mills depend on the operating pressure and type of boiler. This can vary from simple soft water for low-pressure boilers to demineralized, or even polished, makeup water for high-pressure boilers and power turbines.

We provide a variety of applications to help lower costs and increase production, including ultrafiltration pretreatment, industrial softening demineralization, and the polishing of demineralized water or condensates.

Our solutions address:

- Suspended solids removal.

- Industrial softening.

- Demineralization.

- Makeup water polishing.

- Condensate polishing.

Turning waste into a resource

An increase in global and local regulations means pulp and paper plants must become more environmentally responsible, particularly in the development of sustainable waste solutions and residuals management. It’s also a very water intensive, with plants facing increased pressure to reduce its water use.

We offer proven technologies that facilitate waste and process stream treatment to significantly reduce a facility’s water footprint.

Our solutions address:

- Fiber removal.

- Metal removal.

- Suspended solids removal.

- Soluble contaminant removal.

- Organics removal (BOD/COD/TOC).

- Reuse-water corrosion control.

- Selective contaminant removal (metals, heavy metals, and volatile compounds).

- Minimal liquid discharge (MLD).

- Wastewater treatment and reuse.

-

Cooling Tower Water

Preventing water issues that slow production

Like in many processing plants, pulp and paper mills need to deal with challenging cooling tower water. If not properly filtered, cooling tower water can result in scaling, corrosion, and contamination that can adversely affect production.

Our industry-leading knowledge and local expertise in cooling water treatment can help you define a strategic solution that saves money, prevents problems, and helps better manage overall water resources.

Our solutions address:

- Cooling tower blowdown recycle.

- Suspended solids removal.

- Softening.

- Minimal liquid discharge (MLD).

-

Industrial Boiler Feedwater

Lowering costs for production

Water-treatment needs for boiler feedwater in pulp and paper mills depend on the operating pressure and type of boiler. This can vary from simple soft water for low-pressure boilers to demineralized, or even polished, makeup water for high-pressure boilers and power turbines.

We provide a variety of applications to help lower costs and increase production, including ultrafiltration pretreatment, industrial softening demineralization, and the polishing of demineralized water or condensates.

Our solutions address:

- Suspended solids removal.

- Industrial softening.

- Demineralization.

- Makeup water polishing.

- Condensate polishing.

-

Industrial Wastewater

Turning waste into a resource

An increase in global and local regulations means pulp and paper plants must become more environmentally responsible, particularly in the development of sustainable waste solutions and residuals management. It’s also a very water intensive, with plants facing increased pressure to reduce its water use.

We offer proven technologies that facilitate waste and process stream treatment to significantly reduce a facility’s water footprint.

Our solutions address:

- Fiber removal.

- Metal removal.

- Suspended solids removal.

- Soluble contaminant removal.

- Organics removal (BOD/COD/TOC).

- Reuse-water corrosion control.

- Selective contaminant removal (metals, heavy metals, and volatile compounds).

- Minimal liquid discharge (MLD).

- Wastewater treatment and reuse.

Find products for the pulp and paper industry

View a list of products suitable for cooling tower water, industrial boiler feedwater, and industrial wastewater.

Select Pulp & Paper references around the globe

Related resources

See what’s possible

Ask how we can help pulp and paper plants operate at peak levels with effective water management.