Delrin® 100 Series

Article

Delrin® 100 Series Properties and Performance

Mechanical Properties Performance

The resins in the Delrin® 100 acetal homopolymer series are distinguished by their high molecular weight relative to other acetal grades. This identifying feature of these high performance acetal homopolymers, along with their natural high crystallinity, yields materials that have:

- Toughness, high impact strength, high resistance to repeated impact, and high elongation without the need for impact modifiers.

- High mechanical strength and rigidity, without the need for fillers/reinforcements or other modifications.

- Outstanding creep resistance and long-term fatigue endurance.

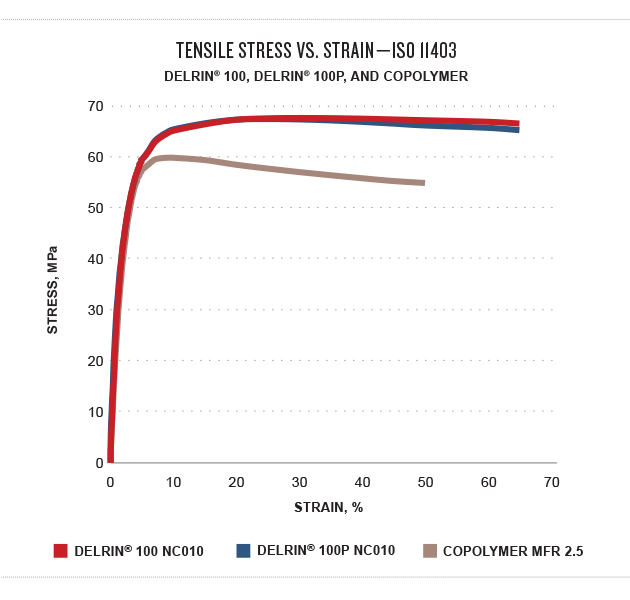

These features of high mechanical strength and toughness can be seen in this overlay of stress-strain curves of high viscosity Delrin® acetal homopolymers and standard acetal copolymers of similar viscosity (Melt Flow Rate of 2.5 g/10 min at 190°C). Delrin® 100 and 100P have very high Tensile Strength and Strain at Break, significantly higher than the standard copolymer. These relative advantages are maintained at elevated temperatures as well.

Performance

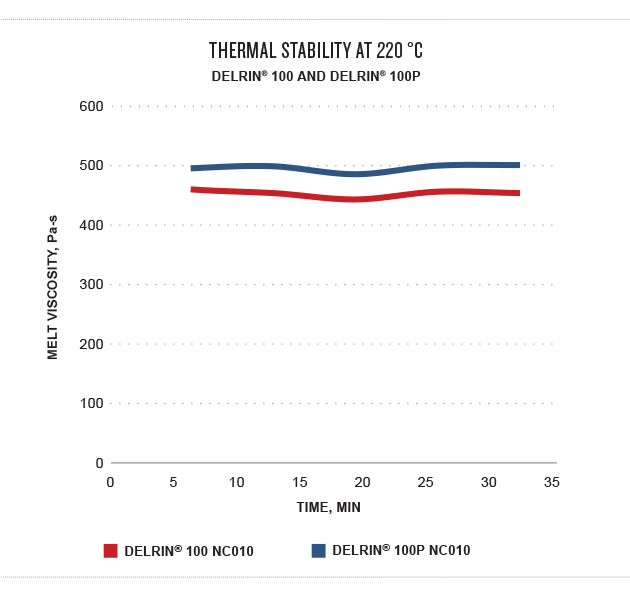

Delrin® acetal homopolymers are readily processed with a variety of molding machines and tooling configurations. The good flow characteristics, fast cycling, and thermal stability of Delrin® grades allow for these materials to be easily molded into complex shapes for parts in demanding acetal applications. Figure 2 demonstrates that the Delrin® 100 series has excellent thermal stability in this test while being held in a capillary rheometer at 220°C at hold-uptimes of up to 30 min, as evidenced by very little reduction in the melt viscosity.

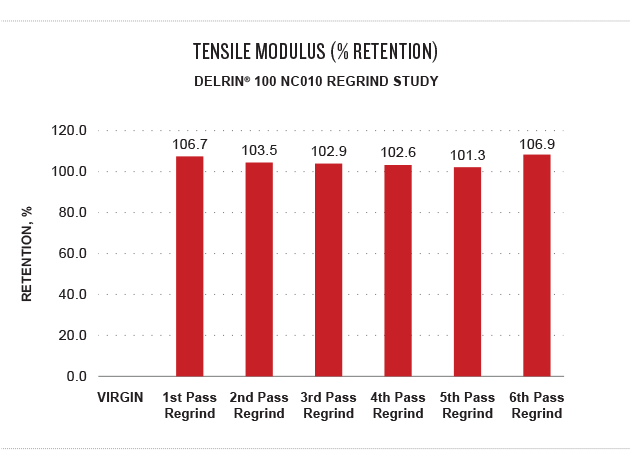

Most molding processes generate excess material from the runner systems, typically at levels of about 30% of the total shot. For optimum productivity, molders generally regrind these runners for blending with virgin resin, depending on parts requirements. When the blend has been processed correctly, original resin properties are well maintained. Figure 3 shows the results of evaluations on molded test bars of Delrin® 100 with up to 5 regrind passes at the extreme of 100% regrind under recommended molding parameters. Even though use of 100% regrind is not common, the graphs show excellent performance through several regrind passes, with the high Yield Stress and Tensile Modulus being retained even under such extreme conditions.

Specific recommendations for optimized processing parameters for molding and proper use of regrind can be found in the Delrin® Molding Guide and the individual resin data sheets. The good processability of Delrin® acetal resins can result in:

- Potential opportunity to reduce cost

- Low levels of rejects

- Part-to-part consistency