Hytrel® Product Portfolio for Wire and Cable Applications

Article | Mar, 25 2021

DuPont™ Hytrel® TPC-ET thermoplastic elastomers

Hytrel® thermoplastic polyester elastomers provide the flexibility of rubber, the strength of plastic, and the processability of thermoplastic. Hytrel® is also available in a full range of Shore D hardnesses (30D to 82D). They possess super hardness and stiffness properties, which allows for a broad scope and great flexibility in wire and cable applications.

Hytrel® is ideal for a number of applications. It offers improved fatigue performance in dynamic cables for off shore wind and marine energy. Plus outstanding flex fatigue performance in an array of drag chain cables/robotics use cases. Hytrel® also provides better “snapback” performance in jacketing and retractable cable for trucks.

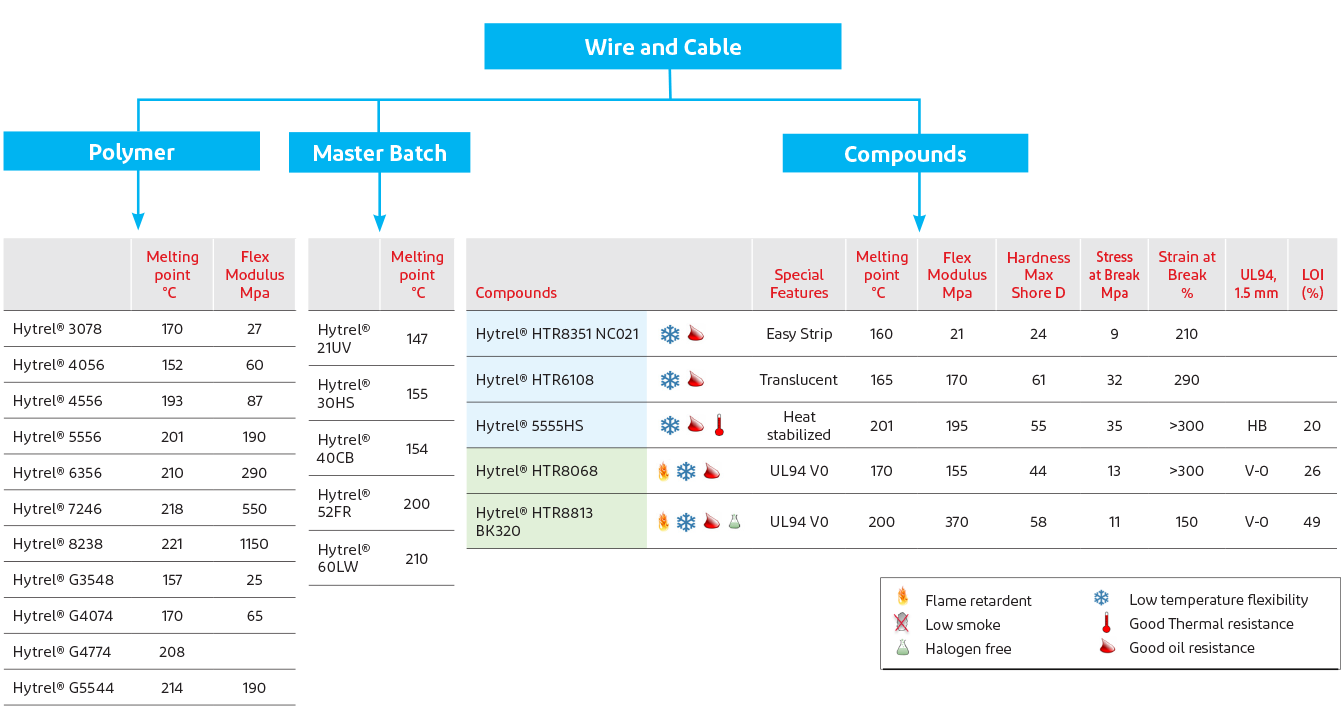

Our polymer, master batch & compounds offerings

Hytrel® Product Line

Hytrel® concentrates

Special grades of Hytrel® thermoplastic polyester elastomer include heat stabilized, flame retardant. Concentrates include black pigments, UV protection additives, heat stabilizers and flame retardants.

Hytrel® for PVC modification

PVC can be modified and compounded in many different ways to achieve specific properties for targeted end uses. Hytrel® can be added to improve mechanical performance, having the major advantage of also softening the final product without the issues of migratory plasticisers.

Hytrel® is a high molecular weight copolyester elastomer and, being a polymer itself, can be easily blended with PVC.

Hytrel® as a polymer does not contain any phthalate plasticiser.

Potential advantages of Hytrel® in a PVC compound:

- Higher softness without any migration issue

- Improved low temperature flexibility

- Better impact strength at low temperature

- Better stability of mechanical performance over a wider range of temperatures

- Increased flex-life

- Improved chemical resistance, specifically oil resistance

Consistent performance over time, especially vs. conventional plasticisers.

Hytrel® for Optical fibers

Key requirements for optical fibers:

- Maintains good signal transmission

– Low shrinkage

– Protects fiber from mechanical damage

– Protects from external environment

– Long life

- Easy handling

– Flexibility (end user, installation)

– Strip-ability (installation)

– Friction against duct (installation)

- Easy Processing & Colorability

Hytrel® 5556, Hytrel® 6356, Hytrel® 7246 or Hytrel® 8238 are ideal materials for optical fibers applications, featuring flexibility and strength, good tear resistance and low CLTE. If you are looking for alternative to PA12, we’d suggest DuPont™ Hytrel® 8238, and if you are looking for easy strip-ability elastomers, then why not DuPont™ Hytrel® HTR8351?

Optical fibers solutions