Crastin® and SiMB for Wire and Cable Applications

Article | Mar, 25 2021

Article

Crastin® and SiMB for Wire and Cable Applications

DuPont™ Crastin® for optical fiber cable applications

Crastin® 6129 NC010

- High viscosity PBT (MFI= 10 g/10min)

- Low shrinkage + post shrinkage behavior, low CLTE (Coefficient of Linear Thermal Expansion)

- High mechanical properties, high impact resistance at low temperature

Crastin® 6130 NC010

- Medium viscosity PBT (MFI= 15 g/10min)

- Better flowability than the Crastin® 6129

Crastin® S600F10

- High viscosity PBT, internally lubricated (MFI= 10 g/10min)

- Good mechanical properties with high elongation at break and good low temperature impact resistance

The benefits of using Crastin® for optical fiber cable

Stable manufacturing processes

- Maintains tubes’ OD/ID (dimensions)

- Fast Line Speed

- Fast start up

Materials mechanical properties allow thin wall constructions and good kink resistance

- High Flexural Modulus & Elongation at Break

- Low temperature impact resistance

Low signal attenuation

- Isotropic Shrinkage, low post shrinkage & CLTE

Consistent performance to Hydrolysis and stress cracking resistance

- Long lasting performance thanks to product quality and durability

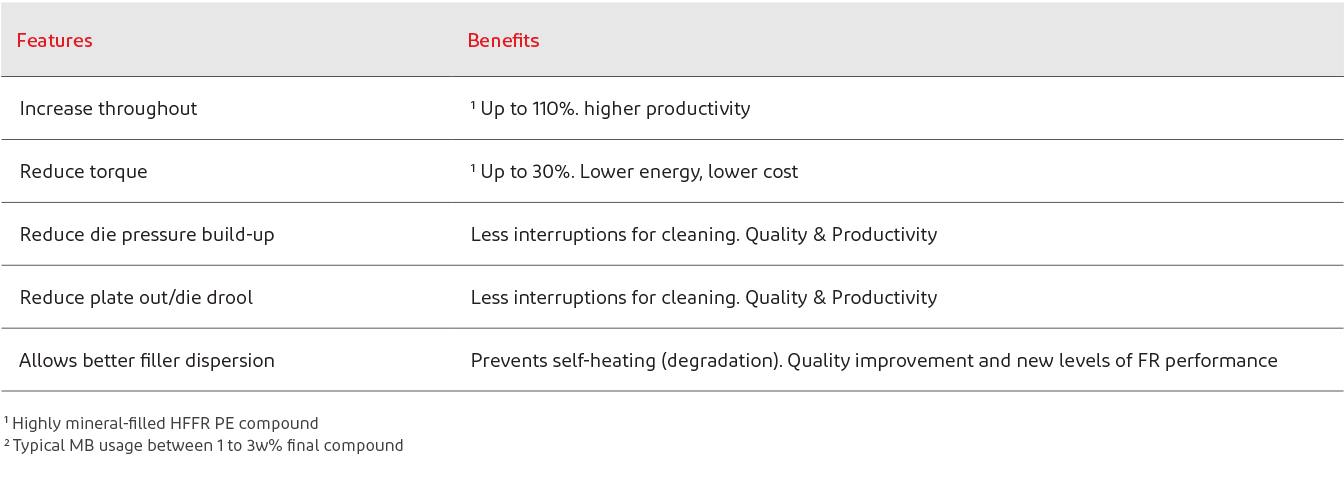

Silicone Master Batch (SiMB) for wire and cable HFFR compounds

Polyolefin HFFR compounds require heavy loading (>65%) of mineral flame retardants such as halogen-free metal hydrates (aluminium hydroxide, magnesium dihydroxide) to meet regulatory requirements.

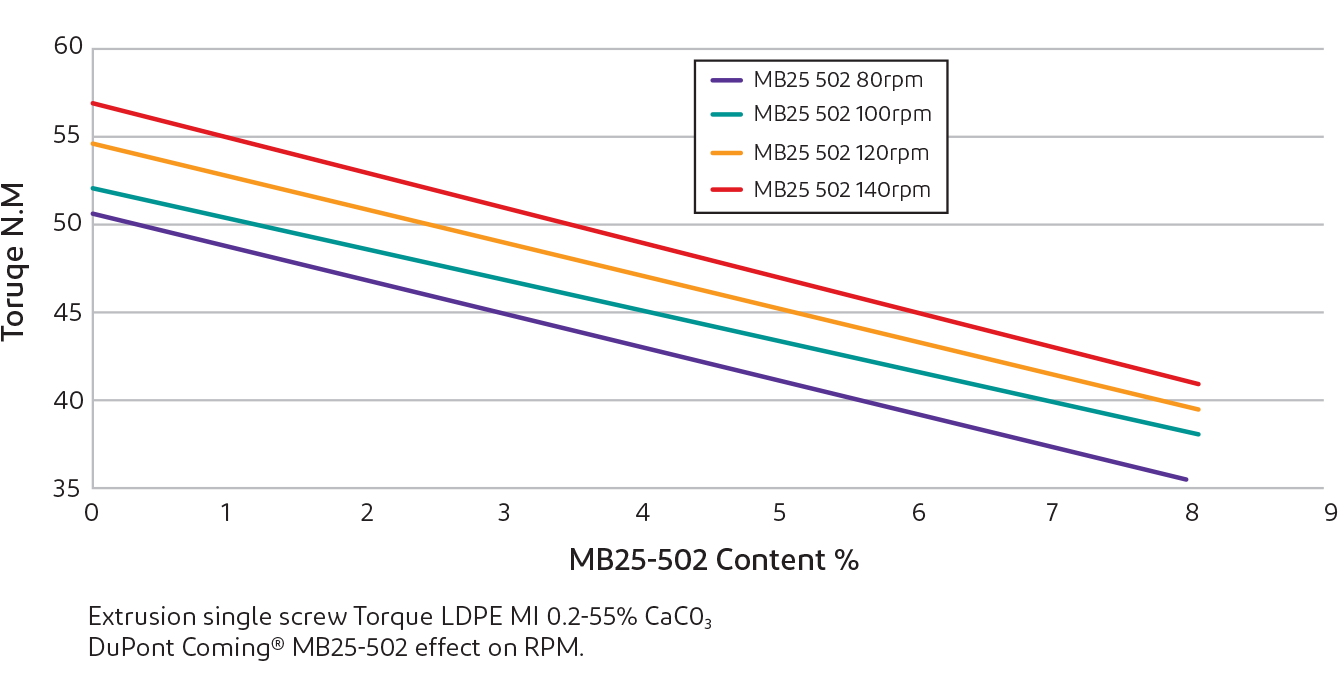

These heavy loaded compounds can induce processing issues during cable extrusion processing of HFFR jacketings: high torque, die build-up, lower throughputs, cable surface aspect, etc.